Hot Selling Windproof Outdoor Pole Accessories Camping Tent Rod Holder

Basic Info.

| Model NO. | WF-JF |

| OEM Service | Yes |

| Service | OEM and Customized |

| Packing | Wooden Cases or Pallets |

| Logo Printing | Customized |

| Cutom Made | Yes |

| Free Sample | Yes |

| Foq | 10-1000PCS |

| Shipping Port | Qingdao, Tianjin, Shanghai |

| Export Markets | Global |

| Transport | by Sea, Rail or Air |

| Place of Origin | Weifang City, Shandong Province, China |

| Technics | Welding |

| Part Type | Welding Parts |

| Item | Tent Bracket |

| Transport Package | Plywood Box |

| Specification | SGS |

| Trademark | OEM |

| Origin | Weifang City, Shandong Province, China |

| HS Code | 7326199000 |

| Production Capacity | 10000PCS/Month |

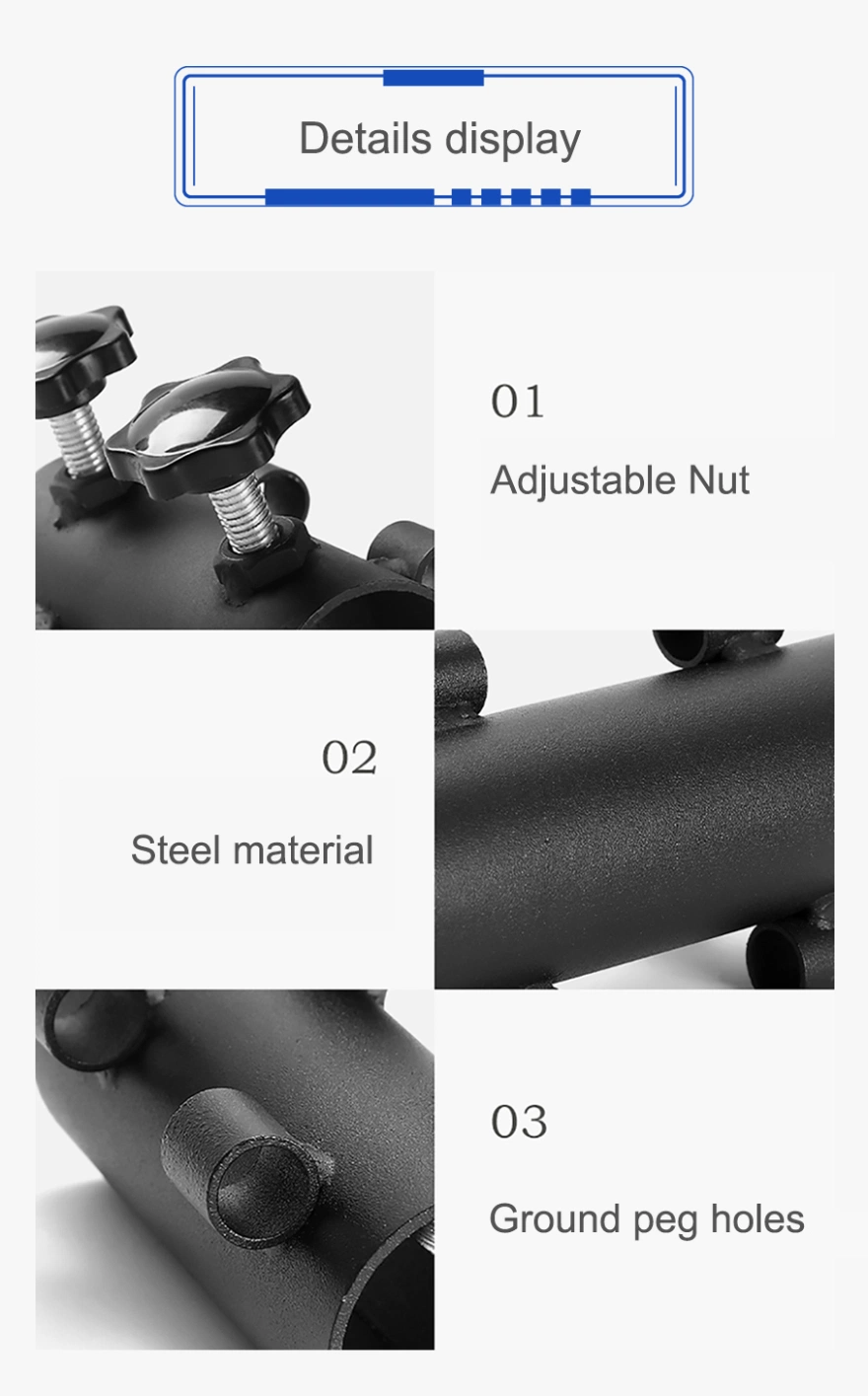

Product Description

Hot Selling Windproof Outdoor Pole Accessories Camping Tent Rod Holder

1, One-stop solution2, Tools designed and built in house3, Fully equipped & Trained4, Consistent quality5, Turnkey manufacturing services6, Excellent communication ability7, Professional & Efficient responsePlace of Origin | Weifang, Shandong |

Brand Name | OEM |

Material | Metal |

Usage | Outdoor |

Feature | Easy Use |

Type | Canopy Stand |

Style | Outdoor |

Material: Stainless Steel/Carbon Steel/aluminumEquipment: Laser welding machinesSurface Treatment: Painting and coating are available

a. We have our own factory.

b. We have a 10 people quality control team.

c. We have our own testing center in our factory.

d. We accept OEM, we can produce parts according to your drawings or samples.

e. All our managers have more than 15 years experience.

Advantages: 1. We are ODM&OEM, design according to your drawing. 2. Rich experience and good technology support. 3. Manufacturer and Trade Company. 4. Low MOQ is accepted. 5. 100% inspection before delivery. 6. Competitive price with high quality. 7. Convenient transportation (Qingdao, Ningbo, Shanghai).Material | Satinless steel,iron,aluminum,alloy,brass etc. |

Tolerance | ±0.02mm |

Size or shape | According to customer drawing or request |

Application | Used Widely |

Drawing accepted | All formats. Such as: cad, pdf, solidWorks,proE,ug,etc. |

Machining | Laser cutting, cnc punching, bending, turning, milling, reviting, welding, polishing, assembly |

Quality Control | ISO 9001,100% QC Test before shipment. |

Surface treatment | Polishing, brushing, chrome,painting, powder coating,hot dip,spraying etc. |

Delivery Time | 7-30 days |

Service mode | OEM or ODM, customized |

Certificate | ISO 9001 |

Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

Experience | OEM & ODM since 2012 |

Robot weldingA robotic TIG (Tungsten Inert Gas) welding center. A robotic MIG (Metal-arc Inert Gas) welding center. Combined with various special fixtures, we can process various complex parts. We can even use automatic welding technology inside the box. Our company philosophy: Attention to Detail. Every quote we send out and every product we made is reviewed by a project specialist and a knowledgeable manager, not simply run through an estimating or design computer. This personal attention,in conjunction with our profession,is what sets us apart from the rest of the field. Competitive pricing. Our plant maybe not huge. Our office possibly is not gorgeous. But we have experienced engineers,well trained technicians and hearts full of responsibility. We run a highly efficient company. We have been always looking for ways to produce a better product at a lower price. Our experience. With around 20 years of experience in the metal processing industry, our knowledgeable team has stood the test of time. We have mastered the art of tooling and fabricating quality product.Customized metal punching auto parts /components,Customized metal stamping auto parts, auto parts. stamping auto parts.

Quality AssuranceWe use modern, up to date equipment, technology and techniques to ensure that high quality goods are consistently produced on time and within budget Quality control are strictly and fully managed from raw material, process control at the producer, QC inspections, process capability studies and final inspection before shipment to assure conformity with customers requirements.

You can look through our website to find your interest or email your any questions throughbelow approach! We will reply to you within 12 hours.